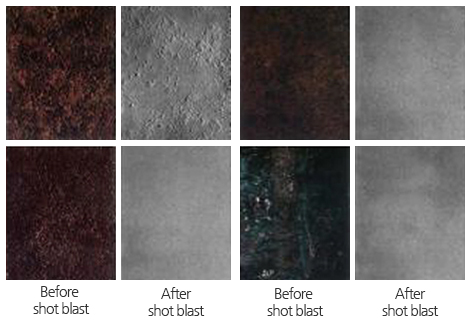

It is a recommended abrasive for shipbuilding, steel bridge, tank, pipeline, steel frame, structure, etc. It is an abrasive material for peridotite type minerals and excellent in hardness and product stability compared to inorganic abrasives including blast furnace slag and PS(Precious Slag) ball. It is an eco-friendly product that has excellent workability in pretreatment and is used as aggregate after use. In addition, we will continue to provide reliable products with continuous R&D in order to replace natural inorganic abrasives.

ㆍ Production Capacity : 500Ton/Mon

ㆍ Grain Size : 0.5 ~ 1.3mm

ㆍ Electrical conductivity : below 15(mS/m)

ㆍ Vickers Hardness : 700~750 (Hv)

ㆍ Without dust clean sand : below 1%

| Chemical Analysis(XRF) | SiO2 | Al2O3 | Fe2O3 | CaO | MgO |

|---|---|---|---|---|---|

| Raw material | 46.55 | 5.08 | 4.32 | 7.88 | 35.45 |

| Fused Silica Mullite | 55.3 | 1.8 | 4.9 | 0.6 | 33.4 |

| Chemical Analysis(XRF) | SO3 | Na2O | K2O | Lol | Total |

|---|---|---|---|---|---|

| Raw material | 0.31 | 0.36 | 0.25 | -0.6 | 99.6 |

| Fused Silica Mullite | 0.31 | 0.36 | 0.25 | -0.6 | 96.32 |

| Classification | Steel Ball | Fused Silica Mullite Grit |

PS Ball | Sand |

|---|---|---|---|---|

| Rockwell Hardness (HRC) | 50 | 60~62 | 43 | 30 |

| Vickers Hardness (HV) |

513 | 700~750 | 423 | 302 |

| Roughness (Quality) |

Very good | Very good | Very good | General |

| Possibility of reuse | 10~12 times | 6~7 times | 2~3 times | possible |

| Equipment change easiness | Difficult | Easy | Easy | Easy |

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

You can email the site owner to let them know you were blocked. Please include what you were doing when this page came up and the Cloudflare Ray ID found at the bottom of this page.